|Mercuries F&B|

Supplier Sustainability Management

Food Supplier Selection Standards

The food suppliers selected by Mercuries F&B Co., Ltd. are legally registered companies (agents/importers) or factories, which is a basic condition. Also, this company adopts system-certified food ingredients or suppliers with priority (e.g., certification of CAS (Certified Agricultural Standard), TAP (Traceability/Good Agricultural Product), TQF (Taiwan Quality Food) verification, FSSC/ISO 22000 Food Safety Management System, and HACCP (Hazard Analysis Critical Control Point)) to control the food safety together.

In 2023, the central kitchen of Mercuries F&B Co., Ltd. cooperated with 105 suppliers, including 101 suppliers in Taiwan which obtained food business registration numbers and 4 foreign suppliers which obtained HACCP certification. There were 67suppliers with the certification of at least one system in Taiwan (accounting for 66 of suppliers in Taiwan), and 70 suppliers which purchased products complying with internationally recognized product liability standards (accounting for 67% of overall procurement). In addition, suppliers of consumables with non-food grade including 21 food ingredient suppliers and 1 packing adhesive tape supplier didn’t obtain system certification yet (accounting for 36% of overall procurement). Most of them were intermediaries or distributors. In order to reduce cost and inventories, the company chose to directly purchase from intermediaries. Currently, these suppliers have been actively included in the food safety system.

Food Supplier Evaluation

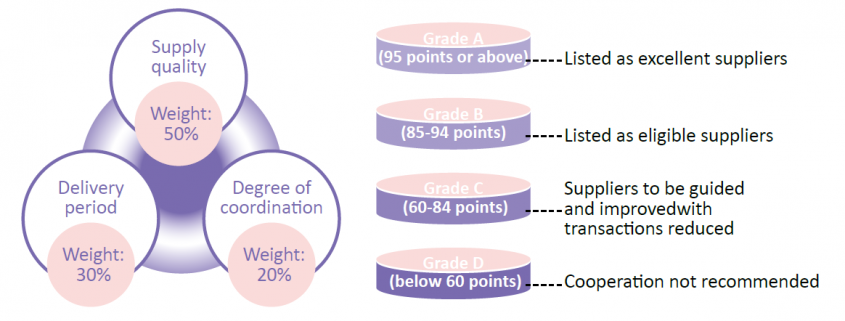

Suppliers who are registered as qualified with continuous transactions will be evaluated quarterly on three aspects: Product quality (weight as 50%), delivery time (weight as 30%), and cooperation (weight as 20%). The evaluation score is divided into four grades as shown in the figure below.

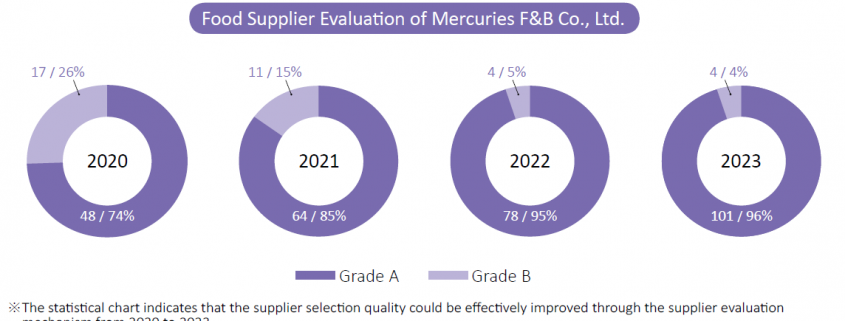

In 2023, Mercuries F&B Co., Ltd. evaluated a total of 105 food suppliers. According to the evaluation results, there were 101 grade A excellent suppliers (accounting for 96%), 4 grade B eligible suppliers (accounting for 4%) and no suppliers of grade C and below. In 2023, the company paid on-site visits to 9 food ingredient suppliers, which was twice as many as the previous year.

On-Site Audits of New Food Suppliers

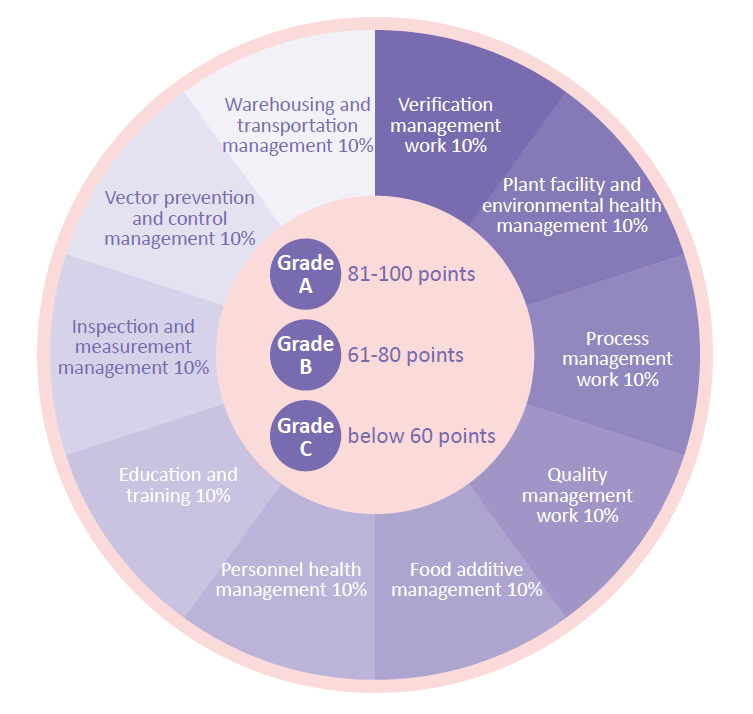

Before cooperation with a newly developed supplier, or transaction of a new raw material, the corresponding grade will be evaluated according to all the certifications of the supplier as well as product inspection reports, e.g., acquisition of Good Hygiene Practices (GHP) and compliance with relevant domestic regulations and rules, as well as other relevant goals. Also, on-the-spot inspection of the manufacturer’s factory will be conducted. The evaluation items are shown in the table below. In 2023, Mercuries F&B conducted on-site visits on 4 new suppliers, and 3 new suppliers underwent written review.

Proportion of Local Procurement

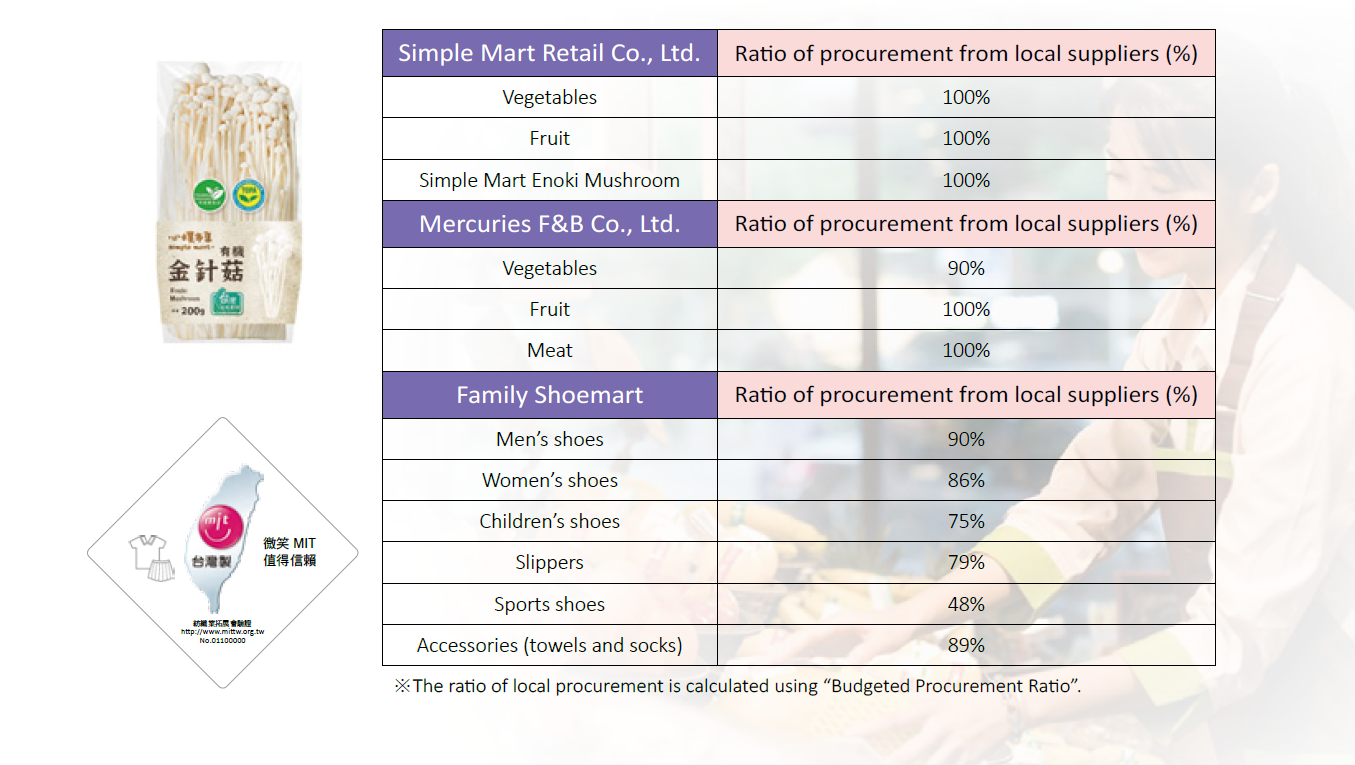

At Mercuries F&B, we uphold a strong philosophy of local support and sustainable development when it comes to the procurement of ingredients. Except for a few imported products, such as beef, cheese, mushrooms, canned tuna, canned pineapple, and deep-frying oil, all other raw materials are prioritized to be sourced from domestic suppliers, accounting for 95% of the total procurement budget. This not only helps to promote local economy and employment, but also helps to establish a healthy supply chain system.

Food Safety and Quality Management

Mercuries F&B Co., Ltd. takes “Food Safety” as the highest principle, deems “Quality Foremost, Safety and Health, and Customer Satisfaction” as the tenet, and adopts the strengthening of source management of raw materials and the reinforcement of process health control as the main strategy.

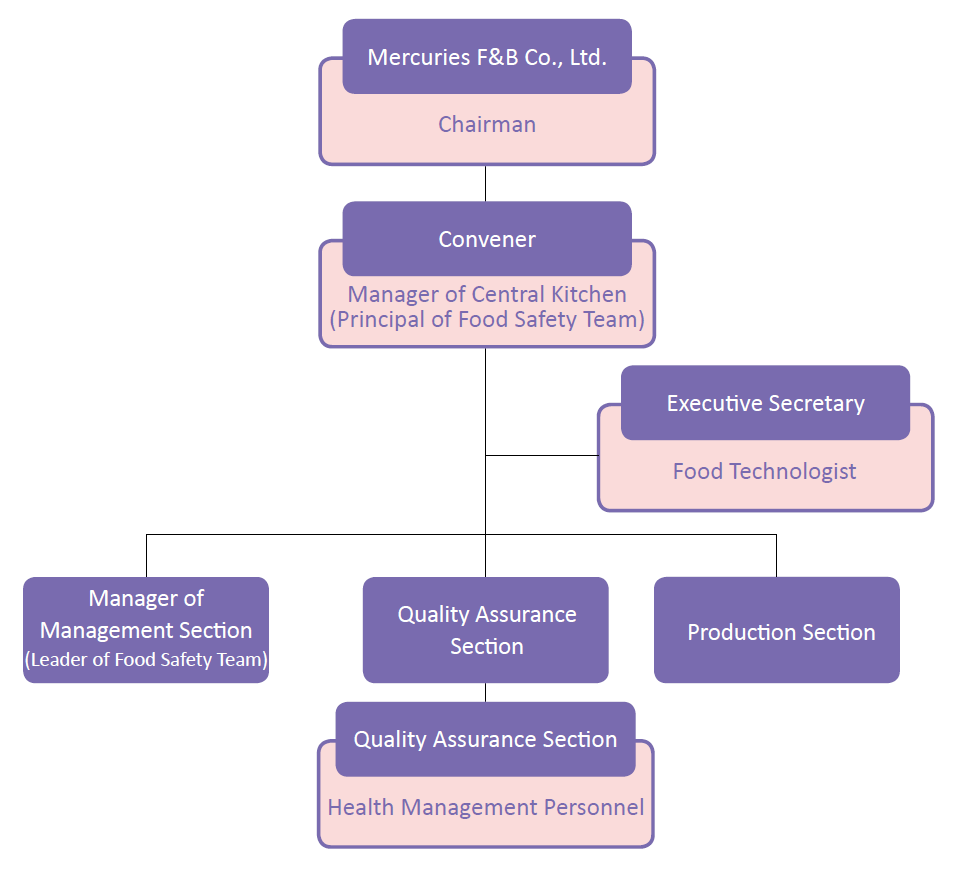

Food Safety Team

Mercuries F&B established the “Food Safety Team” in 2012. Under the leadership of the chairman, the plant director of the central kitchen serves as the convener. The Team gathers members from the Management Division, the Production Division, the Quality Assurance Division, and other related departments, and is committed to reviewing and integrating food safety and quality management. The Food Safety Team holds regular monthly internal meetings. In addition to routine plant operations and food safety and quality-related matters, the Food Safety Team also establishes a corporate food safety culture and sets food safety goals.

Food Safety Management System

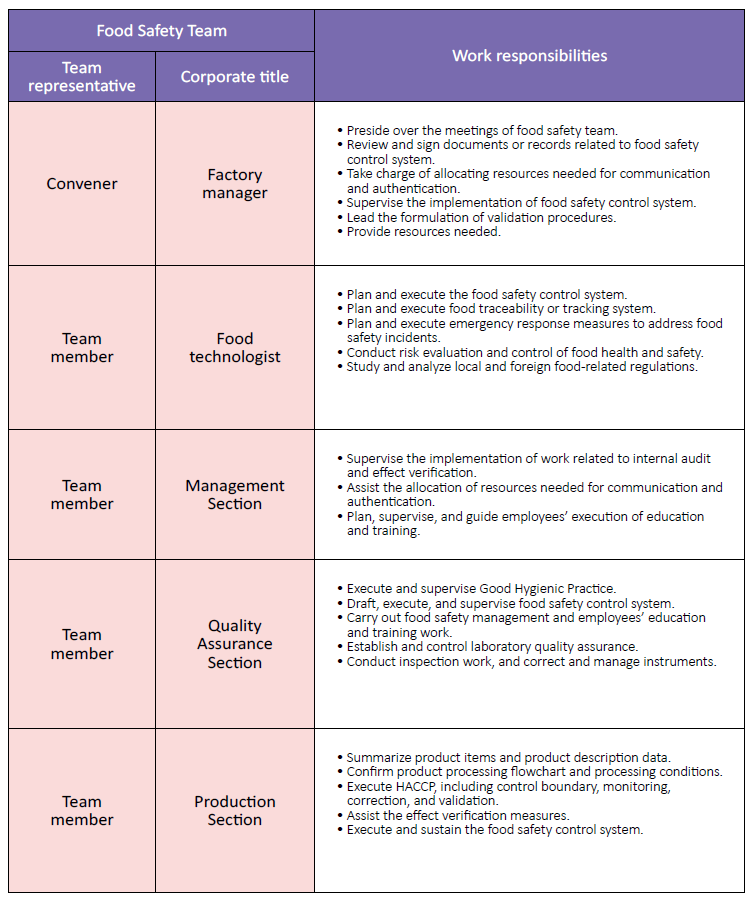

Dayuan Factory of the central kitchen of Mercuries F&B Co., Ltd. completed and acquired the certification of FSSC/ISO 22000:2018 and HACCP in July 2019, completed follow-up inspection in 2022, and smoothly closed renewal review in June 2023. In addition, the flour factory of Dayuan Factory of the central kitchen passed TQF renewal review and obtained a verification certificate in September 2024 and smoothly closed renewal review in September 2025. The company will continue to review the effectiveness and operation status of the food safety management system to assure the effective operation of food safety management.

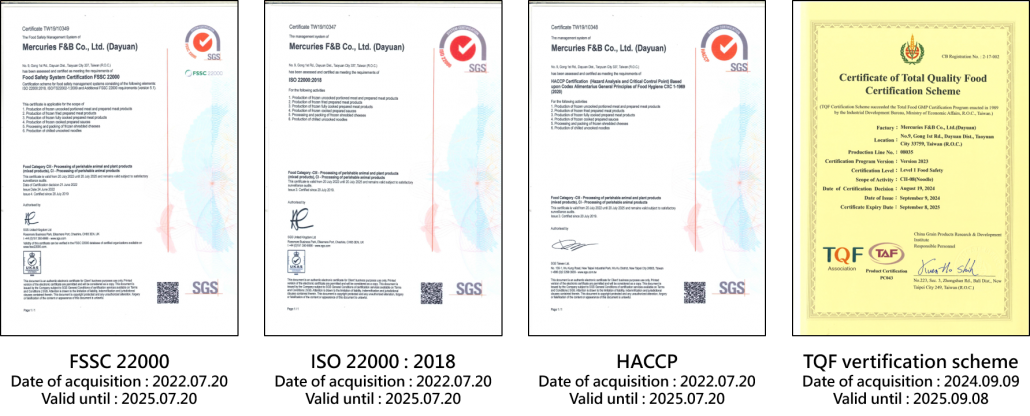

Food Raw Material Management Flow

Mercuries F&B Co., Ltd. implements source management of food raw materials based on “Table of Incoming Inspection of Raw Materials” to ensure that data regarding the raw materials of food ingredients, materials, and food additives used in the catering stores comply with the standards of relevant regulations of the government on food safety and health. Also, this company requires the implementation of relevant work upon inward delivery of the raw materials, including sampling, inspection, recording, and labeling.

The traditional supply chain is based on the mutual trust with the suppliers. However, the reasons for the occurrence of multiple food safety events came from the supply chain. Therefore, this company reviews the quality of its supply chain again, establishes anti-counterfeiting and adulteration identification process, and cooperates with relevant internal departments to ensure the safe and stable supply of raw materials.

Food Safety Monitoring Mechanism

The food safety monitoring mechanism is designed to execute risk evaluation and hazard control in accordance with regulations related to food safety. Mercuries F&B Co., Ltd. implements continual monitoring in the important control processes including sources of raw materials, manufacturing, storage, and sales every year in accordance with HACCP and ISO/FSSC 22000 Food Safety System, to ensure the health management of employees, mechanical equipment, and working environment. Furthermore, it has established inspection plans for raw materials and finished products. These plans have been assured by third-party verification units every year.

Mercuries & Associates Holding leads its subsidiaries to take management responsibilities intensively and duly from source management to manufacturing and processing, with the objective to provide safe and delicious food, and enable consumers to “eat securely”.

Raw Material Monitoring Methods

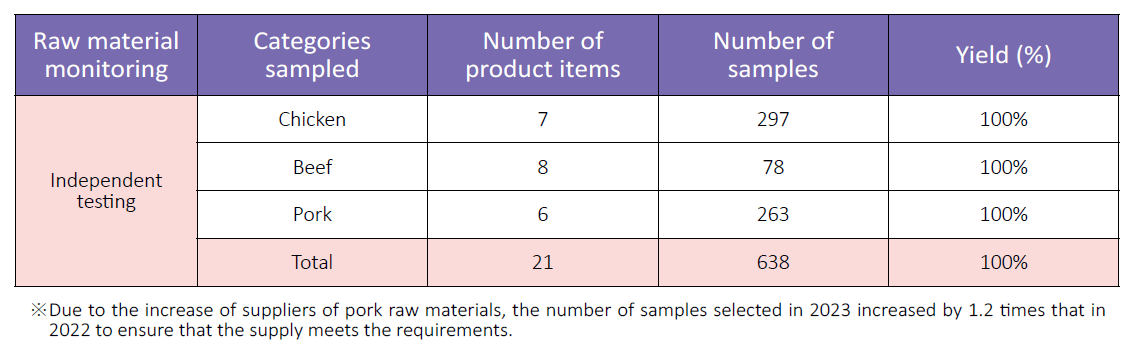

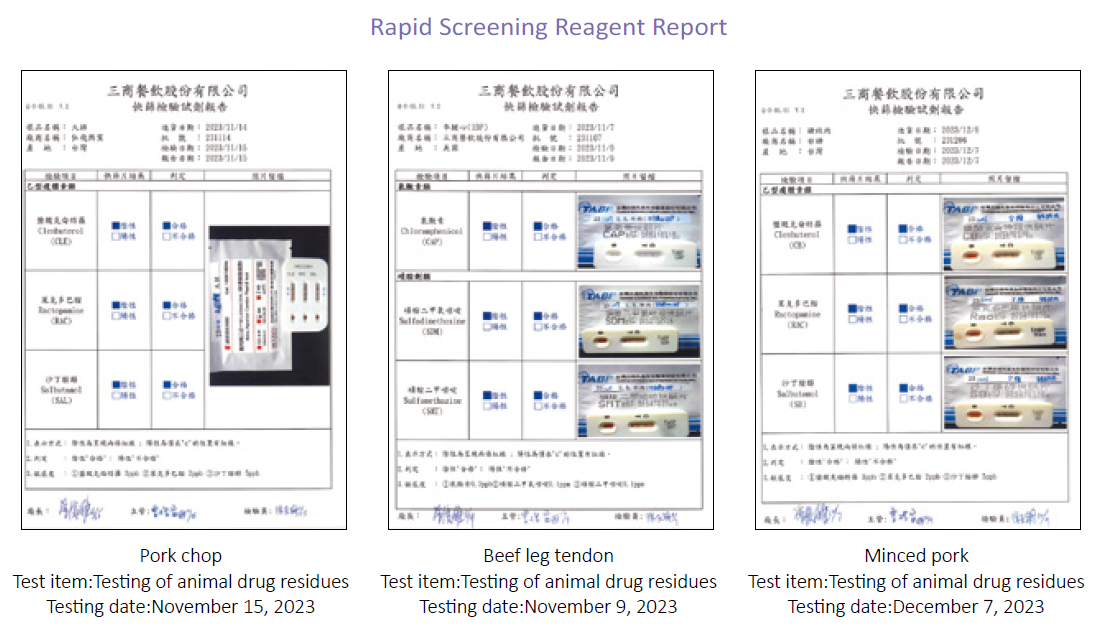

|Independent Testing

Rapid screening of “animal drug residues” is conducted for different parts of various kinds of raw meat in the Dayuan Factory of the central kitchen of Mercuries F&B Co., Ltd. In 2023, 638 samples were selected from the raw materials of 21 product items. The total number of samples increased by 21.1% compared with that in the previous year with yield of 100%.

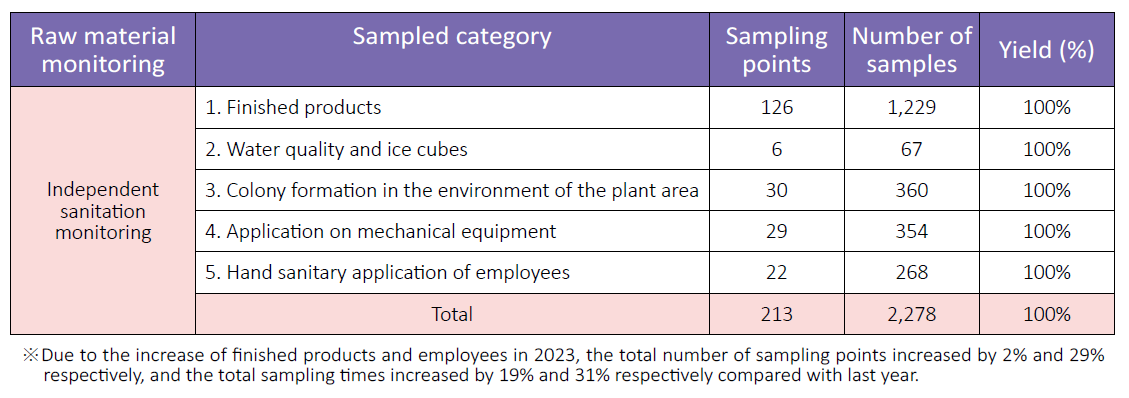

|Independent Health Monitoring

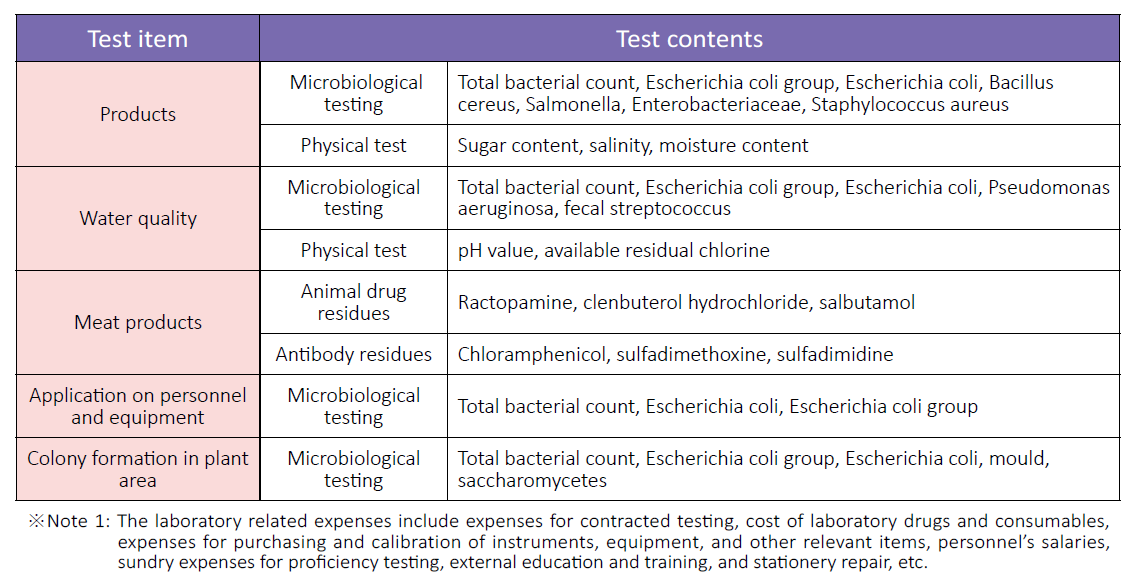

Dayuan Factory of the central kitchen of Mercuries F&B Co., Ltd. conducts independent sanitation inspection of five categories for independent sanitation inspection every month. In 2023, a total of 213 sampling points (product items) were independently inspected with 2,278 sample-times in total and yield of 100%. Due to the increase of the finished product items, the total number of product items sampled increased by 4% .

|Third-party Impartial Unit Testing

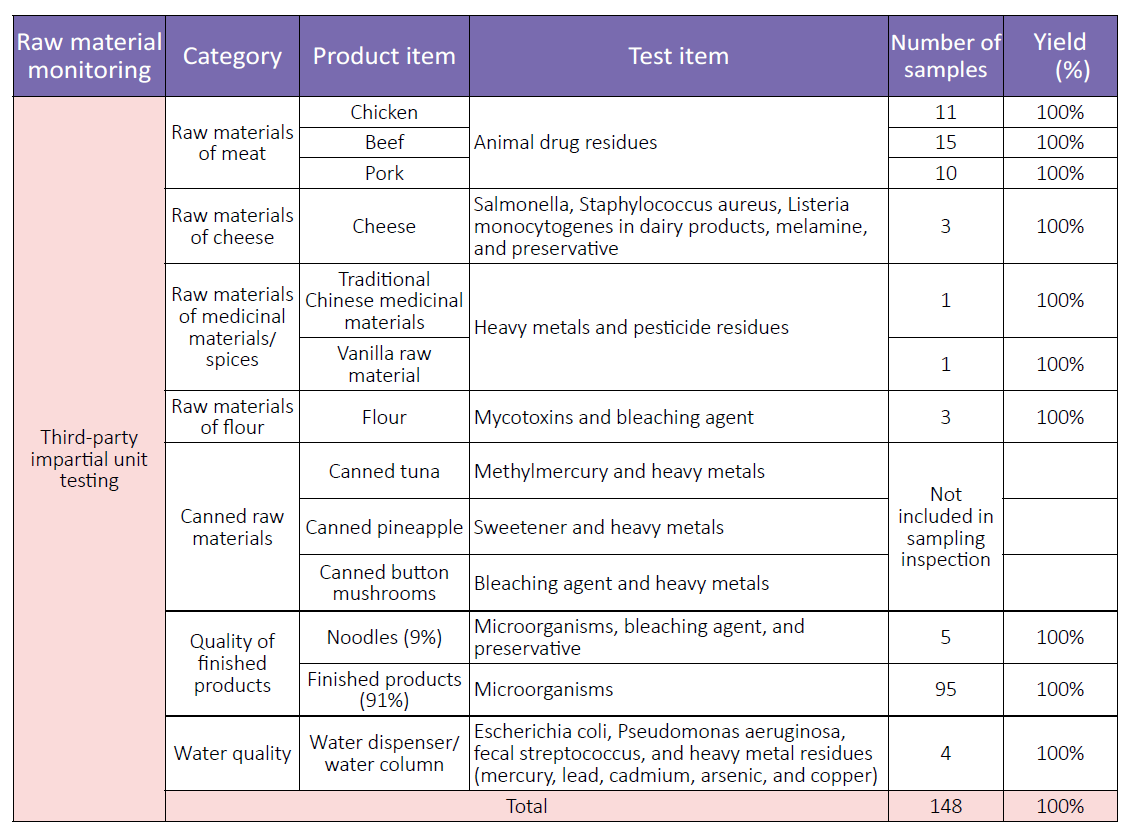

In 2023, Dayuan Factory of the central kitchen of Mercuries F&B Co., Ltd. conducted third-party impartial unit testing of 28 raw material items (accounting for 21% of total number of raw material items), 95 types of finished products (accounting for 95% of the total number of finished product items), and water quality of water dispenser/water column for 4 times respectively in accordance with relevant provisions of the monitoring plans. Also, it adjusts the number of samples according to the number of new products or abnormal conditions taking place every year. In 2023, 148 samples were selected in total. The inspection results were 100% qualified.

In addition, Mercuries F&B Co., Ltd. completed the follow-up inspection of five major products with “Clean Label” in the braising line of the central kitchen (i.e., braised beef soup, stewed beef soup with vegetable and fruit essence, Nanyang Laksa chicken soup, black pepper pork fillet, and curry chicken). The validity period of verification expires on December 31, 2024.

|Strengthen Self-Testing Capabilities

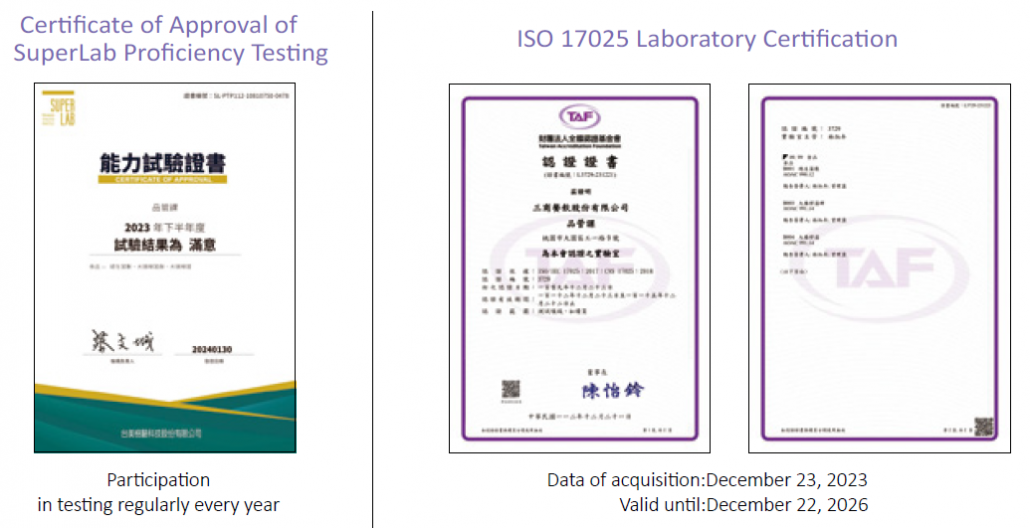

By participating in the proficiency test held by accredited laboratories every year, Mercuries F&B tests and understands the professional competence of the Company’s inspectors to ensure that the quality of ingredients and final products are safe. In December 2023, the inspectors of Mercuries F&B’s Quality Control Section participated in the proficiency test organized by SuperLab, an organization accredited by TAF to conduct proficiency tests in accordance with ISO/IEC 17043. The inspectors passed the tests in the categories of “aerobic plate count (AOAC 990.12)”, “coliform bacteria (AOAC 991.14)”, and “Escherichia coli (AOAC 991.14)”.

In addition, the laboratory of Mercuries F&B received the ISO/IEC 17025 laboratory quality management system certification on December 23, 2020, and completed the extension of the certification in December 2023. This ensures the compliance of the certification system, personnel competence, and testing equipment. In 2023, we upgraded the equipment of our laboratory, including the replacement of probe thermometers, sugar content meters, and electronic scales. We also purchased new equipment such as analog dial thickness gauges and dispensers to improve the efficiency and quality of self-testing. In 2023, the laboratory fees (Note 1) of Mercuries F&B accounted for approximately 0.15% of annual net food operating income.

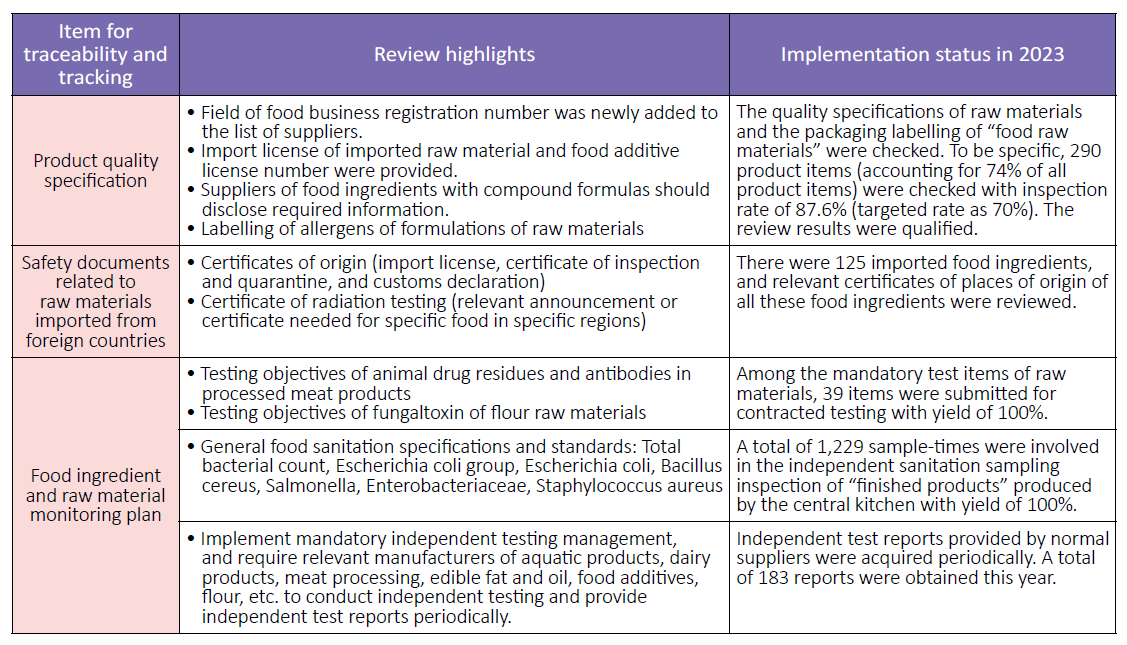

Food Safety Traceability and Tracking

In order to realize the effective traceability of products manufactured in each stage from purchasing of raw materials and production to delivery, Mercuries F&B Co., Ltd. utilizes its internal ERP system to record the basic data of raw materials, products, suppliers, etc., and realize the functions of query of goods purchasing and sales, traceability management, ordering and acceptance, production history registration, and uploading to public cloud. Relying on systematic management, the company strives to reduce manpower and paper work, and strengthen the raw material traceability mechanism that targets at food suppliers.

In 2023, the raw materials used in accordance with the administrative provisions of food regulations of the government included 392 food ingredients and 120 non-food ingredients. Tracking and traceability management was implemented for 100% of food ingredients and 98% of non-food ingredients (the remaining 2% of non-food ingredients were packaging bags).

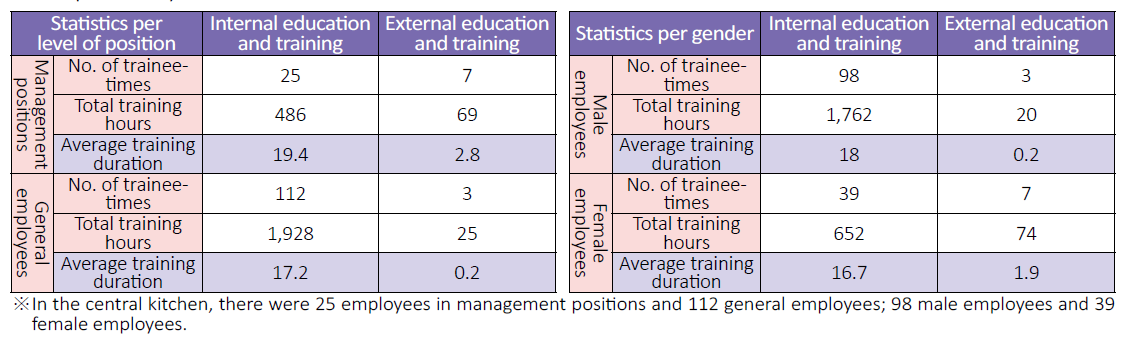

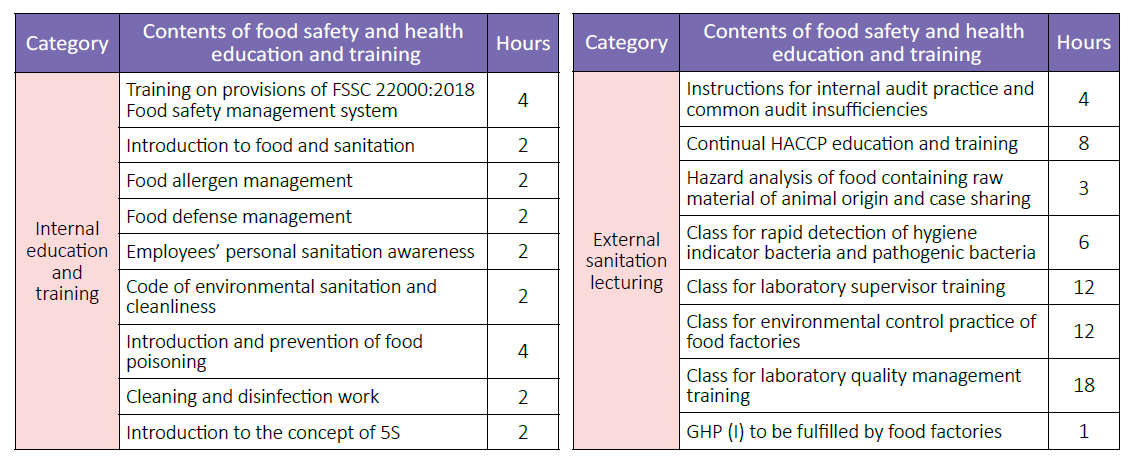

Food Safety and Sanitation Education and Training

The central kitchen of Mercuries F&B Co., Ltd. provides suitable internal and external “Food Safety and Sanitation Education and Training Courses” based on employees’ different work contents, with the objective to strengthen employees’ professional functions, improve employees’ awareness of food safety and sanitation, and lower the food safety and sanitation risks.

In 2023, the central kitchen executed a total of 2,480 hours for all food and safety education and training programs, and the average training duration per capita reached 18.1 hours, down by 34.77% compared with that in the previous year due to the influence of the epidemic.

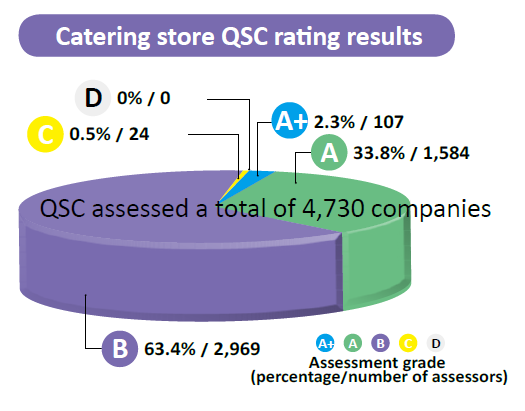

Restaurant Audit System (QSC)

To implement the concept of food hygiene from raw material to table (consumer), in addition to implementing strict control over food safety, Mercuries F&B has also established a restaurant audit system (QSC): food quality management (Quality), service quality (Service) and environmental cleanliness (Cleanliness). The audit team is composed of auditors from the headquarters, and the evaluation results are divided into five levels: A+, A, B, C, and D. The senior executives will also personally visit the restaurant in need of improvement, examine the on-site conditions, and meet with the restaurant manager to fulfill the responsibility of supervision.

In 2023, 4,730 restaurants were audited (an increase of 5.5% compared to last year), and the average monthly audit rate was 99%, an increase of 0.8% compared to last year. Restaurants rated A+ or A accounted for 36.1% of the total restaurants, down 2.7% from last year; restaurants rated C and D were required to submit improvement plans to continuously improve the situation of expired or spoiled food products. As of the end of the year, all of them had made improvements.