|Mercuries F&B|

Energy Management

Mercuries F&B actively made gradual improvements in the procurement of energy saving equipment, replacement of old equipment, and adoption of green and energy saving machinery and equipment. The action plans and project results promoted by the headquarters, restaurants, and central kitchen in 2023 are as follows:

Office Building Energy Saving Measures and Results

In an effort to optimize the performance of the central air conditioning in the Jianbei Building, a plan to replace the old chiller water machine was carried out in early 2021. The total electricity consumption of the building in 2020 is used as the baseline. After replacing the chilled water mainframe, the total electricity consumption was reduced by 10.2% in 2021, 11.4% in 2022, and 9% in 2023 from the baseline. The average annual energy saving benefit remains around 10%.

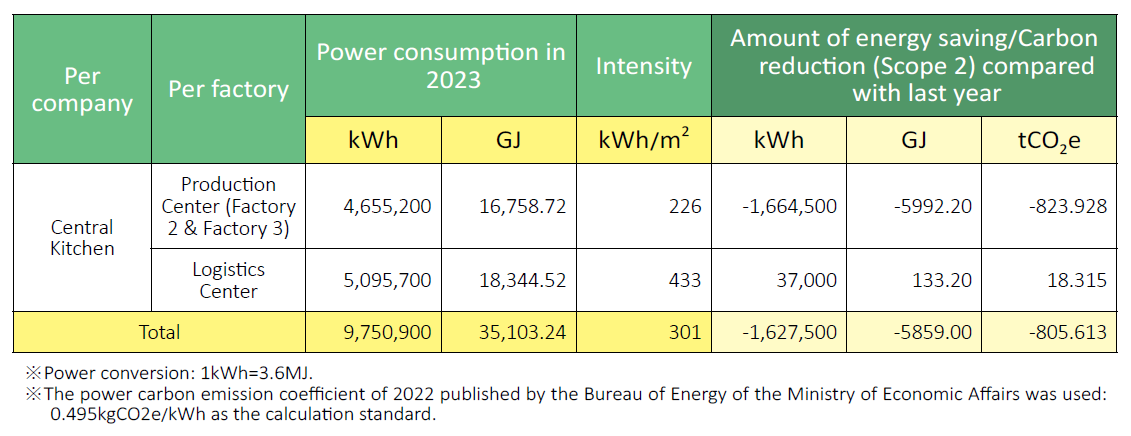

Central Kitchen Energy Saving Measures and Results

- Production centers: There are two food processing plants, both located at No. 9, Gongyi 1st Road, Dayuan District, Taoyuan City. The phase 2 plant (referred to as Plant 2) was put into operation in 2013. After the completion of the dismantling of the phase 1 plant on March 25, 2021, a phase 3 plant (referred to as Plant 3) was planned and constructed on the site. The user license was officially obtained on June 21, 2023. Plants 2 and 3 share the same water and electricity meters.

The production center currently has a contracted capacity of 1,500 kW. Since the raw materials and products of the food processing plant are mostly low-temperature refrigerated/frozen products, electricity consumption is mainly from the “production equipment” and “low-temperature cold chain equipment”. Mercuries F&B has installed variable frequency control for the production equipment with a horsepower over 25HP to achieve energy saving benefits; for low temperature cold chain control, besides installing variable frequency control on the low temperature cold chain equipment of the three plants, a two-stage temperature control has also been implemented. After 12:00am, the temperature will be lowered in stages to achieve the benefit of saving electricity and reducing peak electricity costs. - Logistics Center: It is located at No. 7, Gongyi 1st Road, Dayuan District, Taoyuan City. Its current contracted capacity is 800 kW, and electricity mainly comes from low-temperature storage (refrigeration/freezing) equipment. In addition to inverter control, there are also refrigerating and low-temperature air-conditioning units. Night-time ice storage system: The off-peak electricity consumption after 12:00 at night can be used to store ice in advance for use during the day.

The increase in electricity consumption by the production center in 2023 compared to last year was due to the dismantling of Plant 1 in 2022. The increase in electricity consumption was the completion of Plant 3 in April 2023 and the start of its test run in June 2023. The secondary reason was that the number of chicken products and production capacity in 2023 significantly increased compared to last year, resulting in an increase in electricity consumption. In the future, 2023 will be the baseline year for central kitchen energy reduction comparisons.

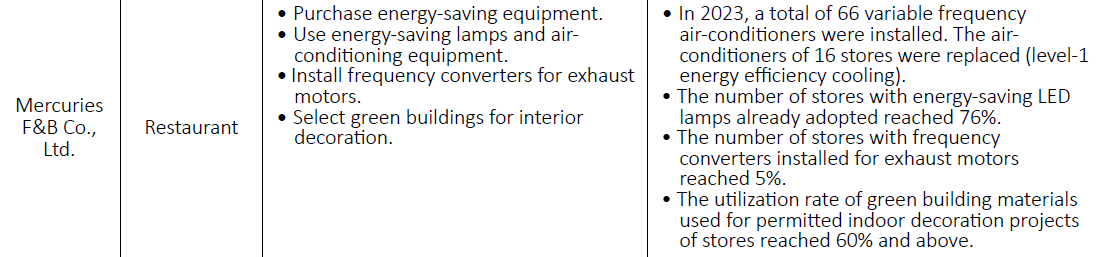

Restaurant

- Energy-saving equipment procurement: In 2023, a total of 66 inverter air conditioners were installed, and old air conditioners were replaced with Class 1 energy efficiency air conditioners in 16 restaurants.

- Use of energy-saving lamps and air conditioning equipment: Adoption of energy-saving LED lamps has reached 76% in the restaurants.

- Installation of inverters on exhaust motors: Installation of inverters on exhaust motors accounted for 5% of all restaurants.

- Use of green building materials for interior decoration: The utilization rate of green building materials in all licensed interior decoration projects in restaurants is over 60%.

Waste Management

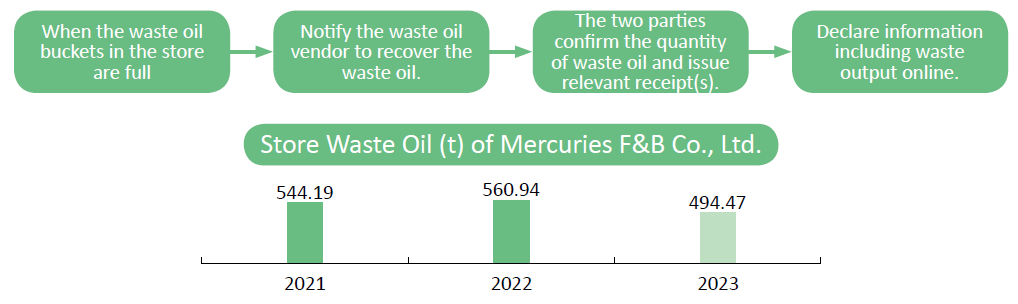

Management of Waste Oil and Food Surplus (Mercuries F&B)

Mercuries F&B has set up recycling facilities and signs in its restaurants to effectively implement food waste recycling. Moreover, business waste disposal plans is submitted to the local EPA according to the Environmental Protection Administration’s “Regulations for Recycling, Clearance and Disposal of General Waste”.

For the waste oil disposal, we have signed a “Waste Clearance Contract” and a “Waste Cooking Oil Contract” with a waste disposal contractor approved by the Environmental Protection Agency. The total waste oil volume of the restaurants of Mercuries F&B was approximately 494.47 metric tons in 2023, down 12% from last year. All removal processes and transportation methods comply with laws and regulations to ensure the flow direction of waste.

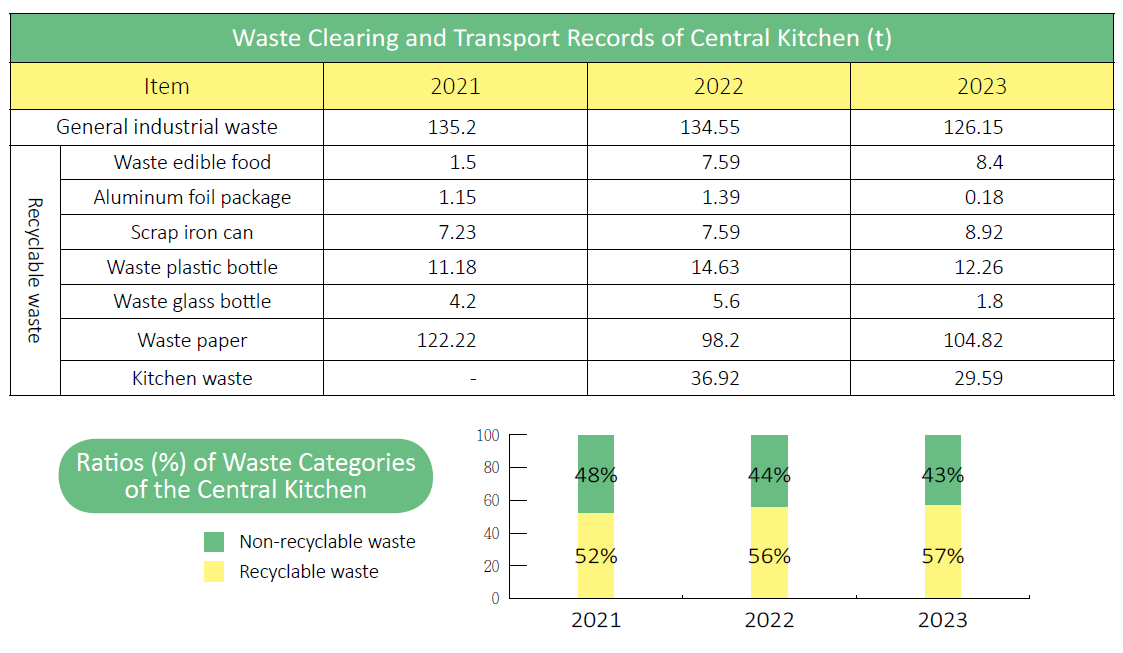

Central Kitchen Waste Management

In 2023, the total volume of waste removed and transported from the central kitchen was approximately 429.96 metric tons, including 126.15 metric tons of general industrial waste; the total volume of recyclable waste was 165.97 metric tons (accounting for 57% of the total waste), and 100% of the waste was recycled.

Wastepaper is recycled by first pressing it into paper bricks with a paper press before being recycled; plastic bottles, glass bottles, iron/aluminum cans, iron drums, and plastic films are sorted and put into space bags before legal manufacturers carry out the recycling process on a regular basis; kitchen waste and scrapped food ingredients are cleared and transported by qualified cleaning operators and then sent to legal livestock farms (pig farms) for disposal.

Water Resource Management

The water resources for the central kitchen are all directly obtained from the Taiwan Water Corporation, and there are currently no other organizations to share water resources.

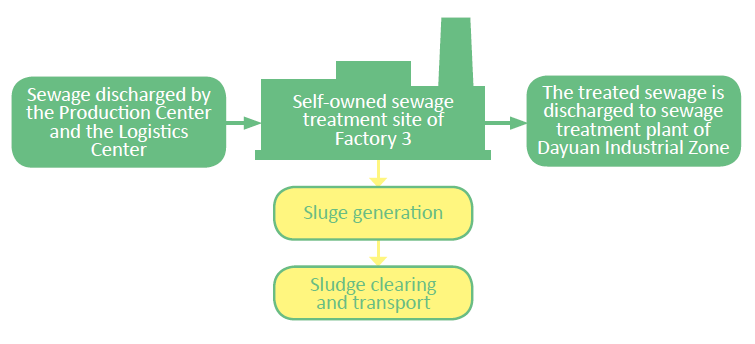

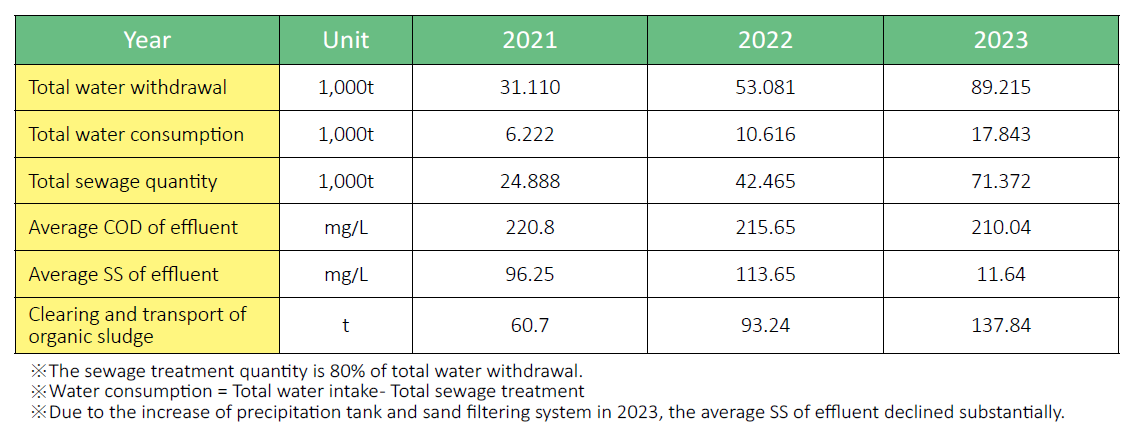

The central kitchen is divided into a logistics center and a production center. The logistics center only discharges domestic wastewater, while the process wastewater from the production center is treated by the wastewater treatment equipment newly built in Plant 3 before being discharged to the Sewage Treatment Plant of Dayuan Industrial Park. At present, approximately 150 metric tons of tap water is consumed each day, and the wastewater treatment equipment can treat approximately 300 metric tons of sewage per day.

In 2021, Mercuries F&B installed pipes from the water tower in the logistics center to the production center. In the event of a water cutoff, the production center can immediately use water resources in the logistics center to avoid the risk of production line interruption. In response to the government’s request, the Company is currently in the process of changing the registration of the merged plant with the merged logistics center and production center. In the future, there will be only one sewage discharge outlet.

Central Kitchen Wastewater Treatment and Sludge Removal

In order to ensure that the quality of wastewater discharged by the Company complies with laws and regulations and reduce the environmental impact, we have continued to update our wastewater treatment equipment and enhanced its maintenance in recent years. We have continued to pursue effective and efficient treatment methods to lessen the environmental burden.

In 2023, the total volume of sludge removal was 137.84 metric tons, an increase of 48% compared to last year. This was mainly due to the limited temporary storage space caused by the construction of Plant 3. The removal frequency has been increased to once every two months. As the drying time was shortened, sludge was heavier.

Environmental Actions and Love the Earth

Bring-Your-Own-Meal-Boxes for Climate Action by “Mom Loves Taiwan”

According to statistics, about 9 billion paper meal boxes (not including plastic tops or other plastic disposable meal boxes) were recycled in Taiwan in 2022, totaling more than 140,000 metric tons. In light of this, Mom Loves Taiwan, a climate action alliance, kickstarted the “bring your own meal box” climate action in 2023. More than 600 food and beverage outlets in Taiwan and remote islands offer various discounts to consumers who bring their own meal boxes, encouraging them to reduce waste and reduce carbon emissions. The 165 restaurants of the subsidiary Mercuries Food Chain also joined other private organizations to become bring-your-own- meal box-friendly restaurants to protect the environment and the earth.

Napoli launched “BBQ Plant-Based Meatball Pizza”

Meat is the main source of protein on the table, making the animal husbandry become a secondary source of carbon emissions following industrial activities. In recent years, consumers’ awareness of environmental protection has risen, and more and more people have begun to choose vegetable diets based on the concepts of environmental protection and animal friendliness, saving energy and reducing carbon emissions. To lead consumers to support environmental sustainability, Napoli, Mercuries F&B’s own brand, teamed up with Taiwanese animal brand “T-Ham” to launch the “BBQ Plant-Based Meatball Pizza”. Through concrete actions, we hope to appeal to the public to consume less meat but more vegetables to cool the earth.

Won the Best Sustainable Packaging Award from Uber Eats

Mercuries F&B has been committed to the food delivery market since the COVID-19 pandemic devastated the catering and retail industries. To maintain a consistent consumer experience both online and offline, delivery materials must meet food safety standards, as well as packaging integrity and environmental protection requirements, doing what we can for the environment. In 2023, we won the “Uber Eats Merchant Partners – Best Sustainable Packaging Award”.